Molykote Coating

Our Service

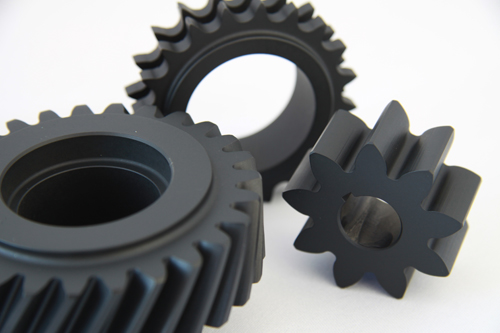

Molykote Coating

Molykote® coatings are anti-friction, solid-lubricant-based coatings designed to improve performance of metal surfaces by reducing wear, friction, and corrosion, especially under extreme conditions (like high temperature, load, or exposure to chemicals).

They are dry film lubricants, meaning they form a bonded lubricating layer that does not drip or attract dirt like oils or greases. Molykote coatings are applied to metal parts that need low friction, wear resistance, or corrosion protection — especially when grease or oil cannot be used. These are ideal for moving, sliding, or threaded components, and for harsh environments like high temperatures or salty air.

| Salt Spray Test (SST) Performance | |||

|---|---|---|---|

| Product | Base Lubricant | SST Performance | Use Case |

| Molykote D-321 R | MoS₂ | > 500 hrs | High-temp sliding parts |

| Molykote D-10 | PTFE | > 240 hrs | Light-load, low-friction coatings |

| Molykote D-96 | MoS₂ + Graphite | 500–1000 hrs | Threads, bolts, cams |

| Molykote D-3484 | MoS₂ + Resin | 1000+ hrs | Automotive bolts & fasteners |

| Molykote 7400 | PTFE + Resin | ~500 hrs | Dry lubrication, wear resistance |